| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : PFT

Model Number : OEM

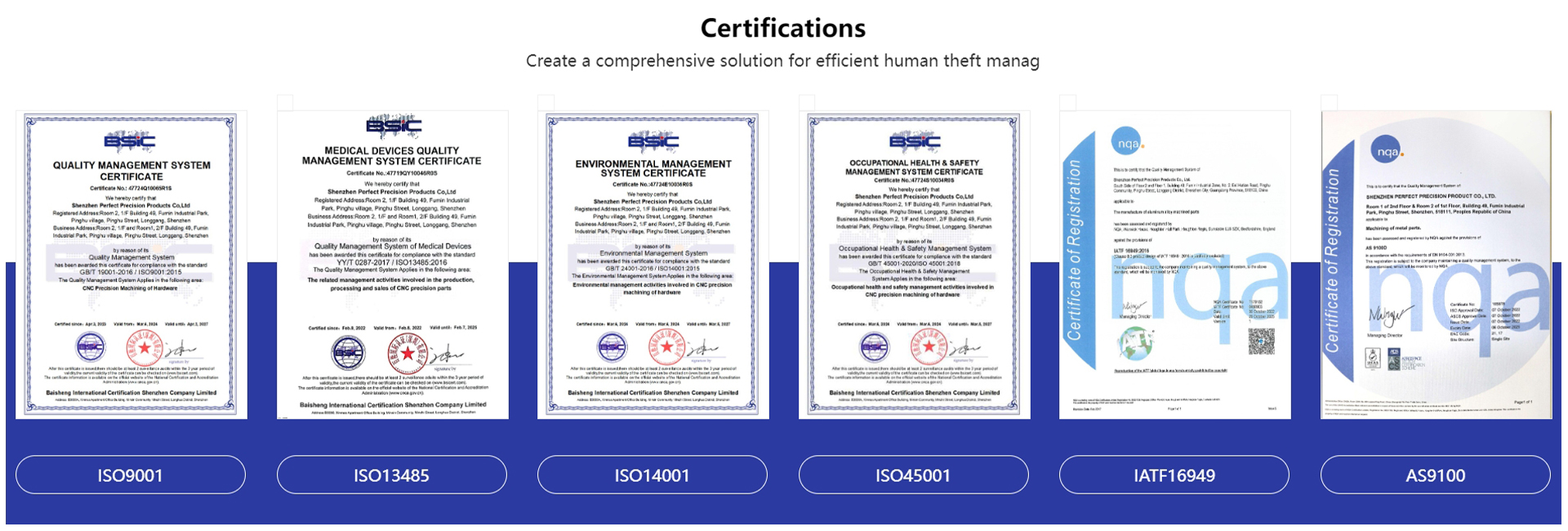

Certification : ISO9001:2015, ISO13485:2016

Place of Origin : Guangdong, China

MOQ : 1PC

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 10000Pcs/ Month

Delivery Time : 7-15 work days

Packaging Details : As the requirement of customer

Customized O Service : OEM & ODM

Process : Turning/Milling/Grinding/Machining

Oem : Available,Offered,Accept

Surface Finish : Sandblasted/ Anodized/ Plated

Oem/Odm : Available

Machine : 5 Axis CNC Machining center

Drawing : 2D/(PDF/CAD)3D(IGES/STEP)

Product Size : 1/2'' 2'' 1-1/2'' and so on

Material Capabilities : Brass,Aluminum

Services : OEM/ODM service

Feature : High Precision

Materials Avaliable : Stainless Steel Aluminum Alloy Brass

Key Word : Brass Flanges Customized Machining Parts

Delivery Timement : 30-35Days

Length : max 1000 (mm)

Ship Method : By express, by air, by se

Size : Customized

Tolerance : ±0.01mm

Heat Resistance : Yes

Precision manufactured CNC brass parts are metal components crafted using CNC machining techniques that ensure high accuracy and tight tolerances. Brass, an alloy of copper and zinc, is chosen for its unique combination of strength, corrosion resistance, and excellent machinability. CNC machining allows manufacturers to cut, drill, mill, and turn brass with remarkable precision, making it ideal for applications that require exact dimensions and performance specifications.

Key Advantages of Precision Manufactured CNC Brass Parts

1.Unmatched Accuracy and Consistency

CNC machining ensures that each part is made to exact specifications with minimal variation. This is crucial for industries where even the slightest deviation from design standards can lead to functional failures or costly rework.

2.Superior Surface Finish

Brass is known for its smooth and attractive finish, and CNC machining enhances this property. The process produces parts with minimal burrs or imperfections, reducing the need for additional finishing work and increasing the overall aesthetic appeal of the product.

3.Corrosion Resistance

Brass is naturally resistant to corrosion and wear, making it ideal for use in environments exposed to moisture or chemicals. This property extends the lifespan of the parts, reducing maintenance costs and downtime for businesses.

4.Customization and Flexibility

With CNC machining, manufacturers can produce brass parts in a wide range of shapes and sizes, from complex geometries to simple, functional components. Customization options also include surface treatments, threading, and other specific characteristics to meet the unique needs of each customer.

5.Cost-Effective Production

CNC machining allows for efficient, high-volume production of precision parts at competitive prices. The ability to automate the process ensures that labor costs are kept low while maintaining the highest standards of quality control.

Applications of CNC Machined Brass Parts

The versatility of precision manufactured CNC brass parts makes them indispensable in a variety of industries, such as:

In the world of modern manufacturing, precision manufactured CNC brass parts offer exceptional value in terms of performance, durability, and cost-efficiency. Whether you're in the automotive, aerospace, electronics, or medical industries, CNC machining provides the accuracy and flexibility necessary to meet demanding production requirements. By partnering with a trusted and experienced CNC manufacturer, you can ensure that your brass components are made to the highest standards, helping your business stay competitive and ahead of the curve.

1. Are you a manufacturer or a trading company?

|

|

Precision manufactured CNC brass parts Images |