In the high-stakes world of advanced manufacturing, where aesthetics meet functionality, stainless steel precision mirror polished parts stand out as the pinnacle of quality and sophistication. These components are not only meticulously engineered for exact performance but are also visually flawless, boasting a mirror-like finish that reflects the commitment to perfection.

What Are Precision Mirror Polished Parts?

Precision mirror polished parts refer to components that have been engineered to extremely tight tolerances and then polished to achieve a reflective, mirror-like surface. This polishing process eliminates even microscopic imperfections, resulting in a flawless, smooth finish that enhances both appearance and performance.

When crafted from stainless steel, these parts gain exceptional durability, corrosion resistance, and mechanical strength, making them suitable for critical environments.

Why Stainless Steel?

Stainless steel is a preferred material for precision and polishing due to its unique combination of properties:

- Corrosion resistance: Stainless steel naturally forms a passive oxide layer, making it ideal for harsh or sterile environments.

- Strength and durability: Offers excellent tensile strength and fatigue resistance, even under extreme temperatures and stresses.

- Hygienic properties: Its non-porous surface resists bacterial buildup, making it suitable for medical and food-grade applications.

- Polishability: Stainless steel can be polished to a high degree of reflectivity, which is essential for decorative and functional applications.

Applications of Stainless Steel Precision Mirror Polished Parts

1.Medical and Surgical Instruments

Mirror-polished stainless steel is essential in surgical tools to ensure sterility, minimize friction, and improve visibility in the operating room.

2.Semiconductor and Electronics Industry

High-purity, polished parts are used in cleanroom environments where contamination must be minimized. Mirror finishes reduce particle buildup and facilitate easy cleaning.

3.Food and Beverage Processing Equipment

The smooth surface prevents bacterial growth and facilitates easy sanitation—critical in maintaining hygiene standards.

4.Luxury Automotive and Marine Trim

Components like exhaust tips, grille trims, and hardware are polished for a premium, long-lasting aesthetic appeal.

5.Optical and Reflective Devices

Mirror-polished stainless steel parts are used in light fixtures, reflectors, and scientific instruments where precision and clarity are paramount.

The Process Behind the Perfection

Creating precision mirror polished stainless steel parts involves a multi-step manufacturing process that demands both technology and craftsmanship:

- Precision Machining: Using CNC machines, parts are fabricated to tight tolerances. This ensures the dimensional accuracy needed for high-performance applications.

- Surface Preparation: Initial grinding removes machining marks and defects. This step is critical to prepare the surface for polishing.

- Mechanical Polishing: A combination of abrasives is used to progressively smooth the surface. This may include belt grinding, buffing, and lapping.

- Electropolishing (Optional): A chemical process that further smooths and passivates the surface by removing a microscopic layer of material. Ideal for high-purity or sanitary applications.

- Inspection and Quality Control: Each part is carefully inspected using tools like surface roughness testers and visual inspection to ensure flawless finish and exact dimensions.

Benefits of Mirror Polished Stainless Steel Parts

- Enhanced Aesthetics: A sleek, reflective surface that elevates product appearance.

- Improved Corrosion Resistance: Polishing removes surface defects that can initiate corrosion.

- Reduced Friction: Mirror surfaces allow smoother movement in mechanical applications.

- Easier Cleaning: Ideal for sterile or clean environments, as dirt and microbes are less likely to adhere.

- Longevity: The durable finish protects against wear, tarnishing, and environmental damage.

| | CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding,3D Printing,Rapid Prototype,Moulds etc. |

| | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

| Titanium: Grade F1-F5 |

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. |

| | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| | ±0.002 ~ ±0.005mm |

| | Min Ra 0.1~3.2 |

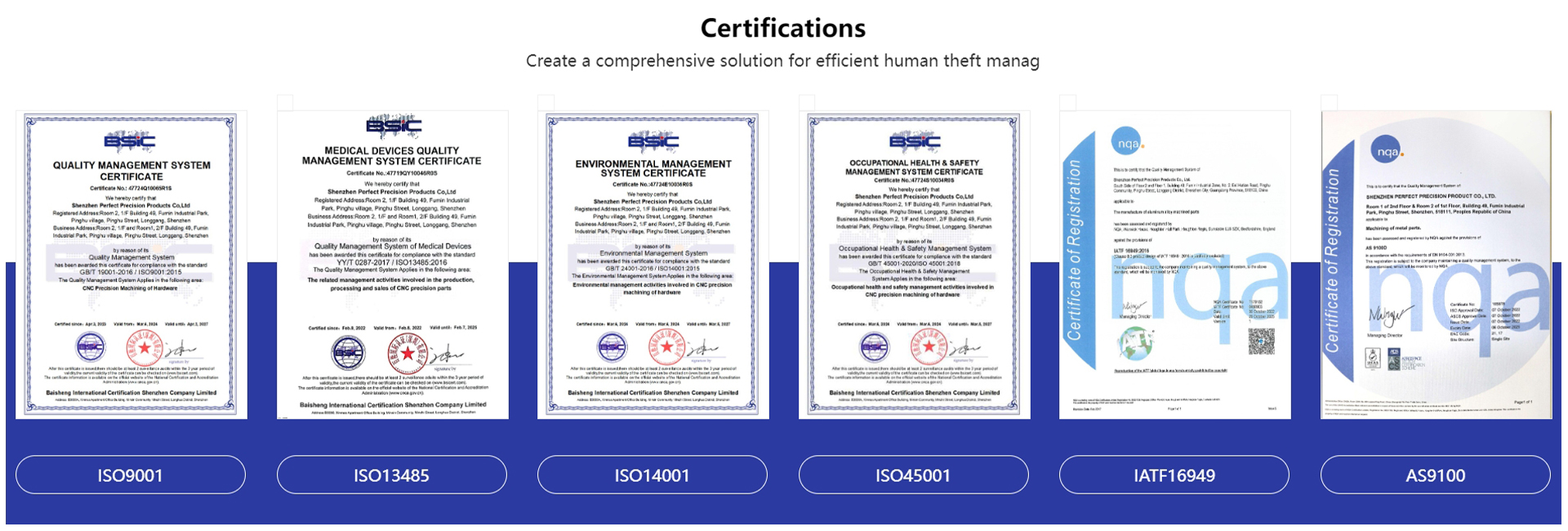

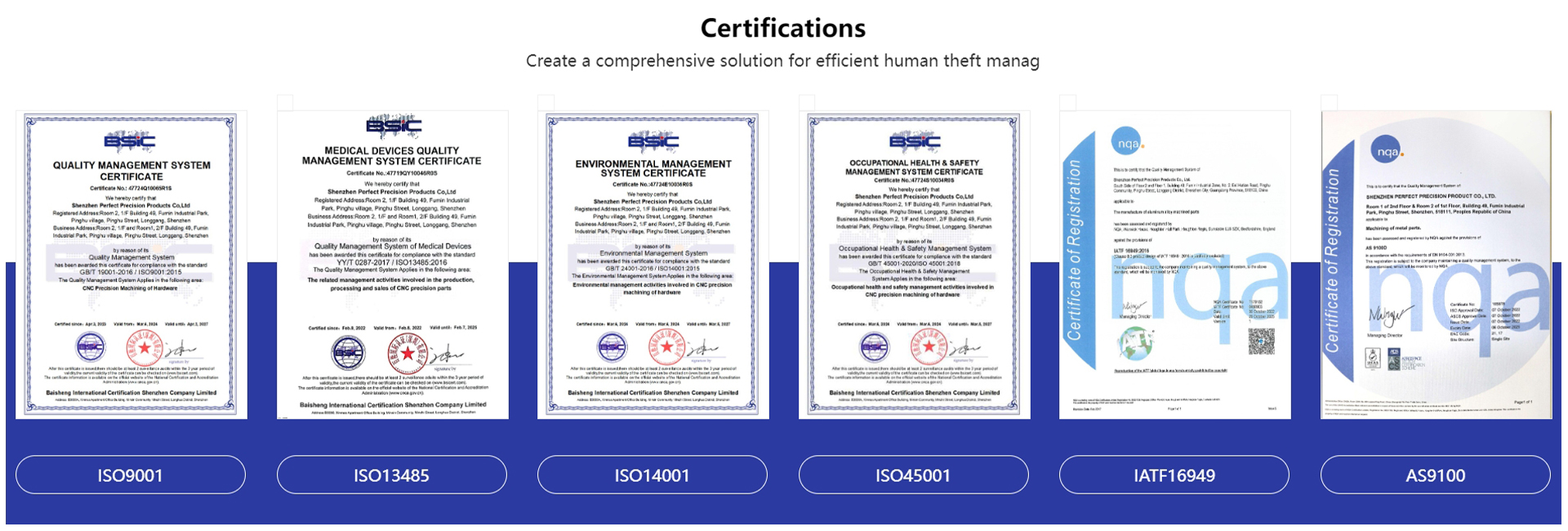

| CERTIFICATE | ISO9001:2015,AS9100D,ISO13485:2016,ISO45001:2018,IATF16949:2016,ISO14001:2015,ROSH,CE etc. |

FAQ

1. Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 20 years of rich experience,

covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings?

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure

critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

|

Stainless steel precision mirror polished parts Images

|