In the realm of advanced manufacturing, the demand for lightweight, durable, and corrosion-resistant components continues to rise. This has made precision aluminum parts CNC machining a cornerstone of production across industries such as aerospace, automotive, medical, and consumer electronics. Combining the versatility of aluminum with the accuracy of CNC machining, manufacturers can achieve consistent, high-quality results that meet the strictest engineering requirements.

Why Aluminum?

Aluminum is one of the most popular materials in CNC machining due to its unique combination of properties:

- Lightweight – Significantly reduces overall component weight, ideal for aerospace and automotive applications.

- Corrosion-Resistant – Naturally forms an oxide layer that protects it from environmental damage.

- High Strength-to-Weight Ratio – Balances strength with minimal mass.

- Excellent Machinability – Cuts cleanly, allowing for faster machining times and finer finishes.

- Conductivity – Offers good thermal and electrical conductivity, useful in electronic housings and heat sinks.

These attributes make aluminum a top choice for manufacturers seeking both performance and cost-efficiency in their precision components.

What is CNC Machining?

CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software directs the movement of machinery and tools. This includes mills, lathes, routers, and grinders. CNC machining is known for its ability to produce complex shapes and tight tolerances with high repeatability—making it ideal for precision aluminum parts.

CNC machines can handle various aluminum grades, including:

- 6061 – General-purpose, highly versatile

- 7075 – High-strength, often used in aerospace

- 2024 – Excellent fatigue resistance

- 5052 – Great corrosion resistance, ideal for marine environments

Benefits of CNC Machining for Precision Aluminum Parts

The synergy between aluminum and CNC machining enables manufacturers to deliver parts that are:

- Highly Accurate – Tolerances can reach ±0.001 inches or better

- Aesthetically Refined – Smooth finishes and fine detailing are achievable

- Rapidly Prototyped – Ideal for low-to-medium volume production with fast turnaround

- Consistently Repeatable – Digital control ensures every unit is identical

- Customizable – Allows complex geometries and part features such as threads, pockets, and undercuts

These characteristics are particularly critical in industries where functionality and appearance are equally important.

Applications Across Industries

Precision aluminum parts CNC machining supports a wide variety of use cases, including:

- Aerospace: Brackets, housings, structural components

- Automotive: Transmission parts, custom mounts, lightweight frames

- Medical Devices: Instrument casings, surgical tool handles, diagnostic housings

- Consumer Electronics: Enclosures, heatsinks, interface panels

- Robotics and Automation: Gears, arms, camera mounts, end effectors

In each of these sectors, CNC machining offers the precision, consistency, and scalability needed to meet both prototyping and production demands.

CNC Machining Processes for Aluminum Parts

Machining aluminum involves several key CNC operations:

- Milling: Ideal for removing large volumes of material, creating slots, pockets, and contours

- Turning: Best for cylindrical components such as bushings, pins, and threaded parts

- Drilling: Accurate hole making and tapping for mechanical fasteners

- Finishing Processes: Anodizing, powder coating, bead blasting, and polishing enhance surface performance and aesthetics

Advanced 3-axis, 4-axis, and 5-axis CNC machines allow the creation of intricate aluminum parts with minimal setups, reducing lead time and improving accuracy.

Quality Control in Precision CNC Aluminum Machining

Given the critical roles that aluminum parts play in modern systems, quality assurance is non-negotiable. Leading manufacturers implement:

- Dimensional Inspection using CMMs (Coordinate Measuring Machines)

- In-process Monitoring with real-time feedback systems

- Material Certification to ensure the correct aluminum grade and treatment

- Surface Finish Testing to verify cosmetic and functional requirements

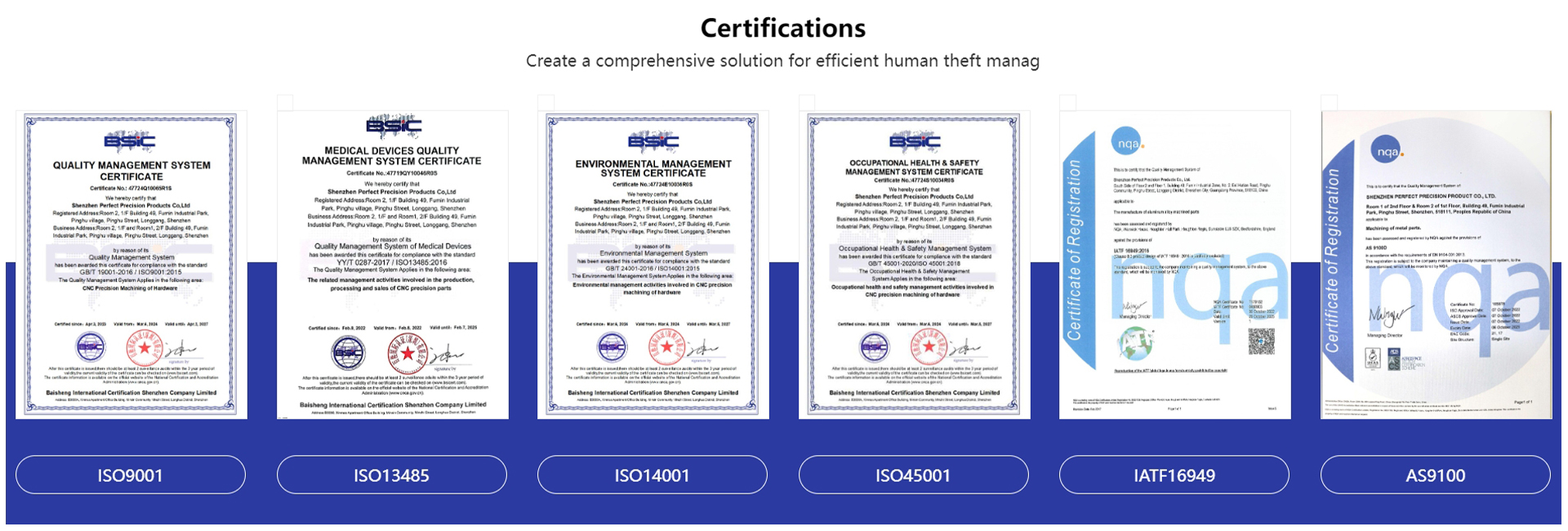

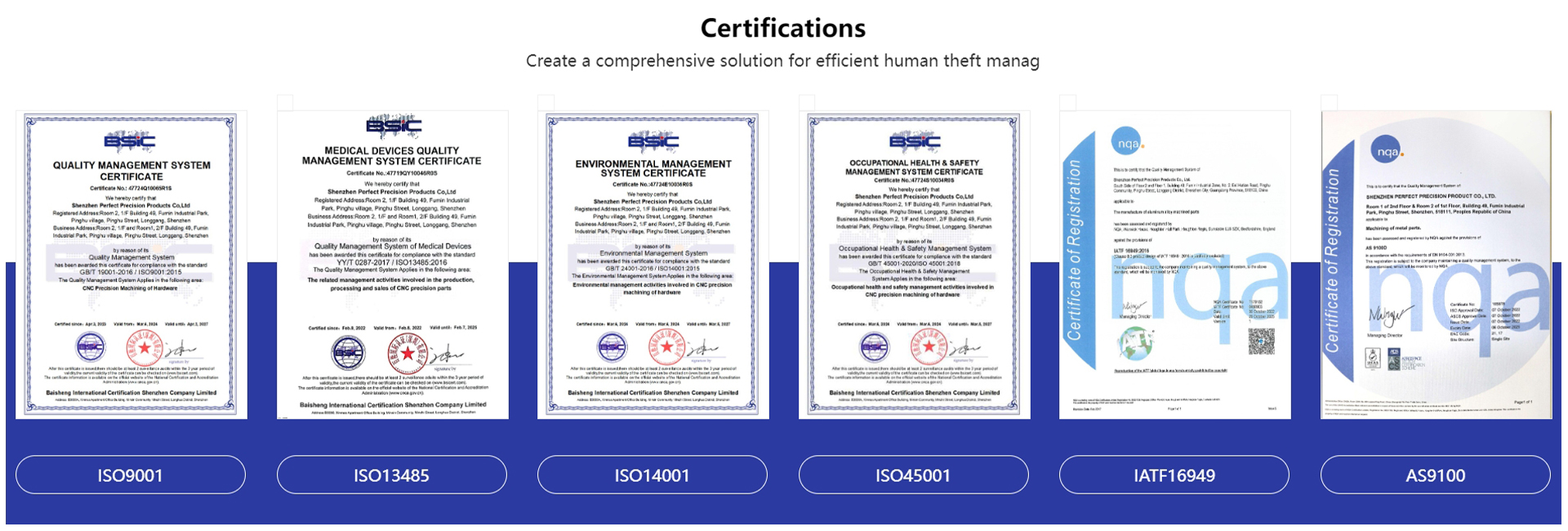

Consistent adherence to ISO 9001, AS9100, or medical-grade standards (ISO 13485) ensures compliance with industry regulations and customer expectations.

Looking Ahead: CNC Machining and Industry 4.0

As digital transformation accelerates, CNC machining of aluminum parts is integrating with Industry 4.0 technologies such as AI-driven process optimization, IoT-enabled equipment monitoring, and digital twins. These advancements further increase the precision, traceability, and scalability of aluminum machining processes.

| | CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding,3D Printing,Rapid Prototype,Moulds etc. |

| | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

| Titanium: Grade F1-F5 |

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. |

| | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| | ±0.002 ~ ±0.005mm |

| | Min Ra 0.1~3.2 |

| CERTIFICATE | ISO9001:2015,AS9100D,ISO13485:2016,ISO45001:2018,IATF16949:2016,ISO14001:2015,ROSH,CE etc. |

FAQ

1. Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 20 years of rich experience,

covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings?

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure

critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

Product Tags:

|

|

Precision aluminum parts CNC machining Images

|