In the realm of precision manufacturing, CNC (Computer Numerical Control) machining has revolutionized the production of stainless steel components, offering unparalleled accuracy and repeatability. When combined with meticulous polishing processes, these components achieve both functional excellence and visual appeal.

Advantages of CNC Machining for Stainless Steel Parts

- Unmatched Precision: CNC machining enables the creation of intricate designs with tight tolerances, ensuring each part meets exact specifications.

- Complex Geometry Capability: Advanced CNC techniques facilitate the production of components with complex shapes that are challenging to achieve with traditional manufacturing methods.

- Consistency and Repeatability: Once programmed, CNC machines can produce identical parts consistently, which is crucial for high-volume production.

The Role of Polishing in Enhancing Stainless Steel Components

While CNC machining defines the form and structure of stainless steel parts, polishing refines their surface, offering both functional and aesthetic benefits:

- Improved Corrosion Resistance: Polished surfaces are less prone to harboring contaminants, enhancing the material's resistance to corrosion.

- Enhanced Visual Appeal: A mirror-like finish elevates the aesthetic quality of components, making them suitable for applications where appearance is paramount.

- Reduced Friction: Smooth surfaces minimize friction, which is beneficial for parts involved in moving assemblies.

Applications of CNC Machined and Polished Stainless Steel Parts

The combination of precise machining and high-quality polishing makes these parts ideal for various industries:

- Medical Equipment: Components such as surgical instruments and implants require both precision and a polished finish to meet stringent hygiene standards.

- Aerospace: Parts subjected to high stresses benefit from the strength of stainless steel, while polished surfaces reduce aerodynamic drag.

- Consumer Electronics: Casings and connectors demand precise dimensions and a polished look to align with modern design aesthetics.

Conclusion

Integrating CNC machining and polishing processes in the production of stainless steel parts results in components that excel in precision, functionality, and appearance. By collaborating with specialized manufacturers, industries can obtain parts that not only meet technical requirements but also enhance the overall product quality and user experience.

| | CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding,3D Printing,Rapid Prototype,Moulds etc. |

| | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

| Titanium: Grade F1-F5 |

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. |

| | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| | ±0.002 ~ ±0.005mm |

| | Min Ra 0.1~3.2 |

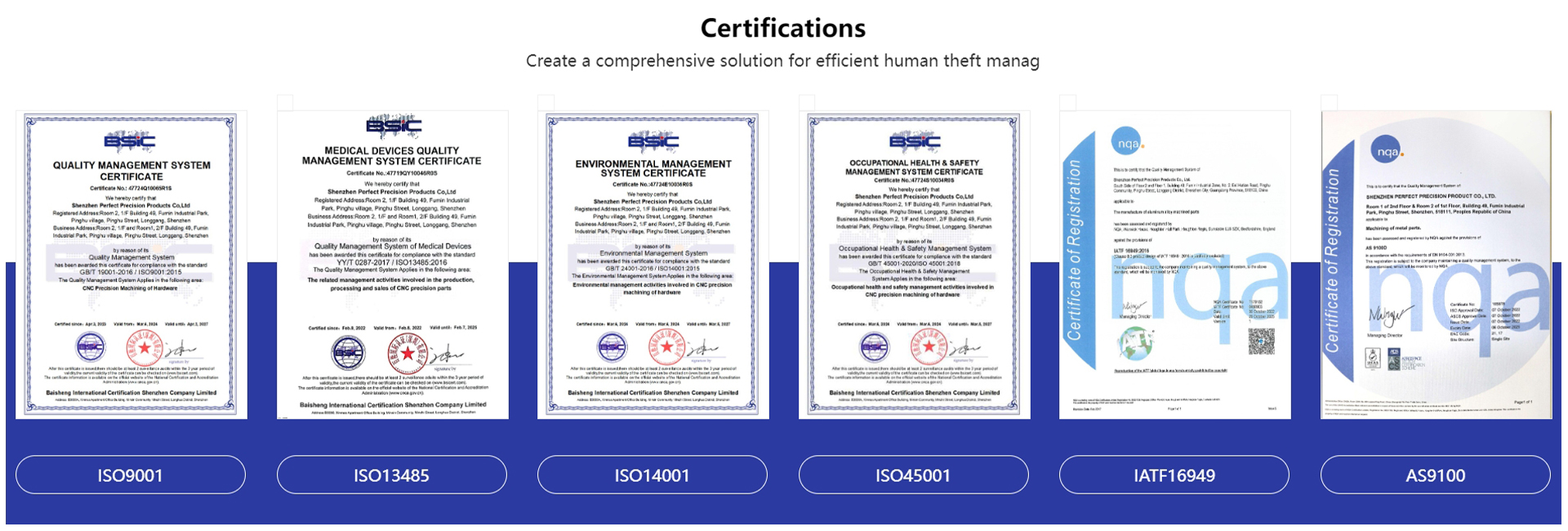

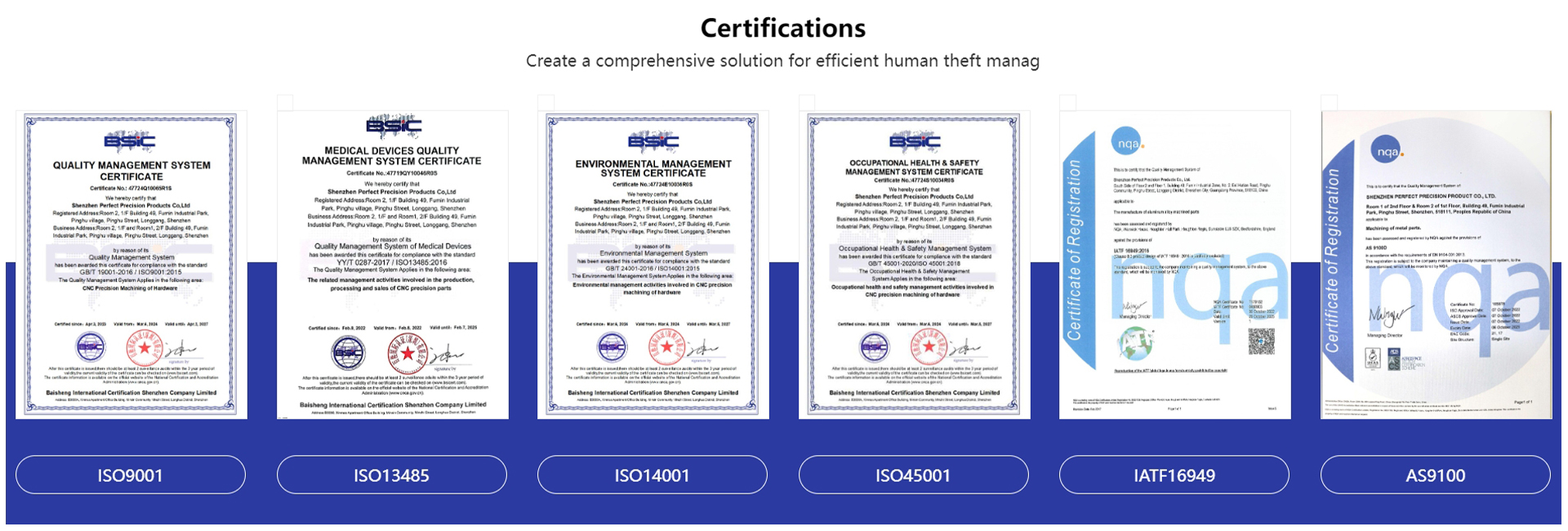

| CERTIFICATE | ISO9001:2015,AS9100D,ISO13485:2016,ISO45001:2018,IATF16949:2016,ISO14001:2015,ROSH,CE etc. |

FAQ

1. Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 20 years of rich experience,

covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings?

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure

critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

Product Tags:

|

|

CNC stainless steel parts precision machining and polishing Images

|