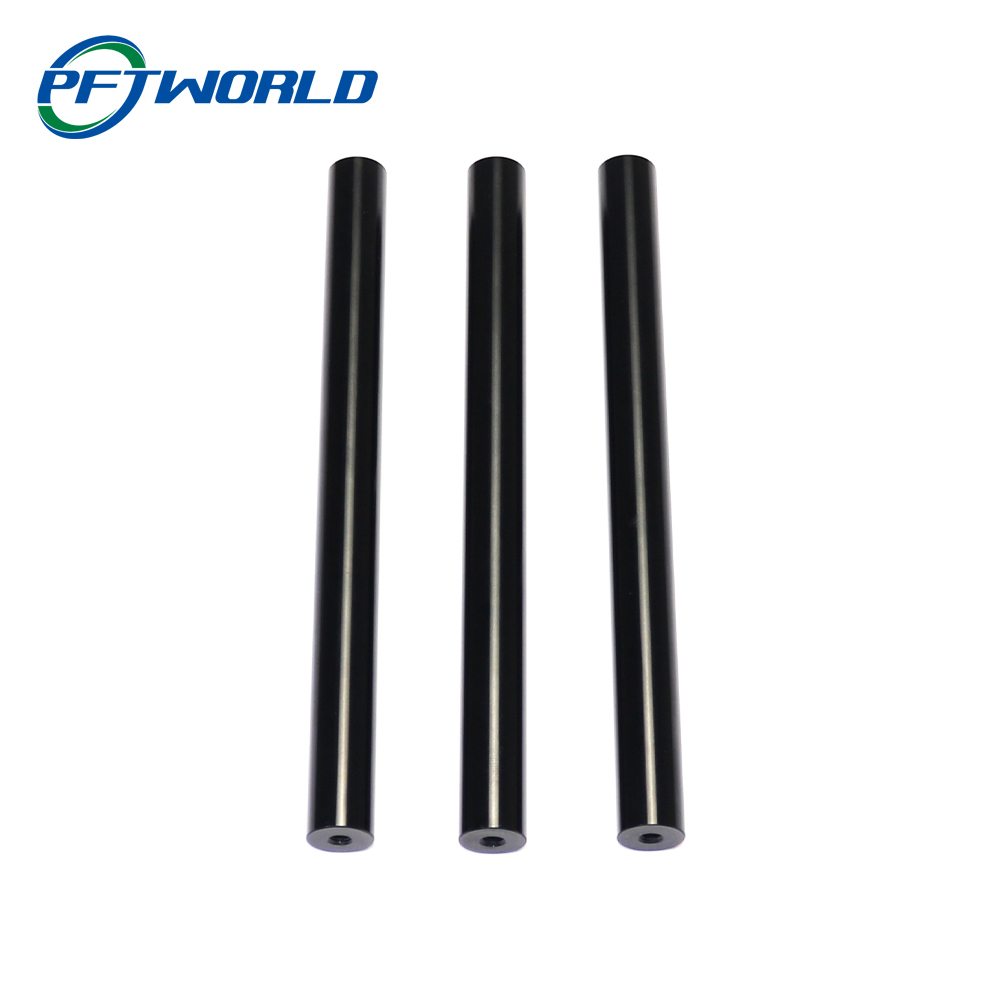

So you need a long, sleek, black aluminum part that has to be machined to perfection. Maybe it's a rail for a high-end piece of tech, a structural component for an aerospace application, or a custom heatsink. You're thinking about three things: length, precision, and that durable black finish.

The Challenge: Why "Long" is a Big Deal

First off, machining a long, skinny piece of aluminum isn't like machining a small, chunky block. It's like trying to sharpen a very long pencil without it snapping. Here’s why:

- Vibration & Chatter: During CNC milling or drilling, long pieces can vibrate. This leads to inaccurate cuts, a poor surface finish, and even tool breakage.

- Sagging: Aluminum isn't ridgid. A long piece can sag under its own weight, meaning the middle won't be straight or level during machining.

- Heat Management: Machining generates heat. On a long part, uneven heat can cause it to expand and warp slightly, throwing off your tight tolerances.

CNC Machining: Making the Cut

The CNC process is where your part gets its critical features. For a long aluminum piece, we typically start with an "extrusion" or a long bar of "bar stock."

- Milling: This is how we create slots, holes, mounting points, and complex contours along the length of the part.

- Drilling & Tapping: Precise holes for screws and fasteners are drilled along the axis.

- The Goal: The machinist's job is to hold incredibly tight tolerances (often within ±0.05mm or better) over the entire length of the part, ensuring it's straight and true.

The Magic of Black Oxidation (Anodizing)

You don't just want it long and precise—you want it black. For aluminum, that almost always means Type II or Type III (Hardcoat) Anodizing.

This isn't paint. It's an electrochemical process that grows a super-hard, corrosion-resistant layer on the surface of the aluminum. Then, we dye it black and seal it. Here’s why it’s perfect:

- Durability: The anodized layer is incredibly scratch-resistant and won't chip or peel like paint.

- Aesthetics: It gives a deep, uniform, matte-black finish that looks professional and technical.

- Functionality: It protects against corrosion and can even provide some electrical insulation.

Where You See These Parts in the Real World

This isn't just a theoretical exercise. These long, black, precision parts are everywhere:

- Aerospace: Rails and tracks inside aircraft and satellites.

- Optics & Photonics: Mounting rails for lenses and lasers (like dovetail rails).

- Robotics: Structural framing and protective covers.

- High-End Consumer Tech: Supports and housings for premium audio/visual equipment.

- Medical Devices: Components for imaging machines and surgical equipment.

The Bottom Line

Creating a long, black, precision-machined aluminum part is a perfect example of manufacturing synergy. It requires:

- Expert CNC machining to handle the challenges of length.

- Smart design that anticipates the anodizing process.

- Skilled anodizing that knows how to handle and finish long parts without flaws.

When done right, the result is a incredibly strong, lightweight, durable, and great-looking component that’s ready for serious work.

| | CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding,3D Printing,Rapid Prototype,Moulds etc. |

| | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

| Titanium: Grade F1-F5 |

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. |

| | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| | ±0.002 ~ ±0.005mm |

| | Min Ra 0.1~3.2 |

| CERTIFICATE | ISO9001:2015,AS9100D,ISO13485:2016,ISO45001:2018,IATF16949:2016,ISO14001:2015,ROSH,CE etc. |

FAQ

1. Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 20 years of rich experience,

covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings?

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure

critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

|

Aluminum Long Piece, Black Oxidation, CNC Machining Images

|