| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : 7 Swords

Model Number : OEM

Certification : CE

Place of Origin : Shenzhen.China

MOQ : 1PCS

Price : $5-100

Payment Terms : T/T, L/C, D/P

Supply Ability : negotiable

Delivery Time : about 7-20 days according to the quantity

Packaging Details : PP bag. Plastic box. Tin box.etc

Material : aluminum, brass, copper, Stainless steel, titanium

Process : CNC turning

Service : OEM/ODM,Customized OEM,One Stop Service

Tolerance : ±0.03mm

Technology : 15 Years Experience

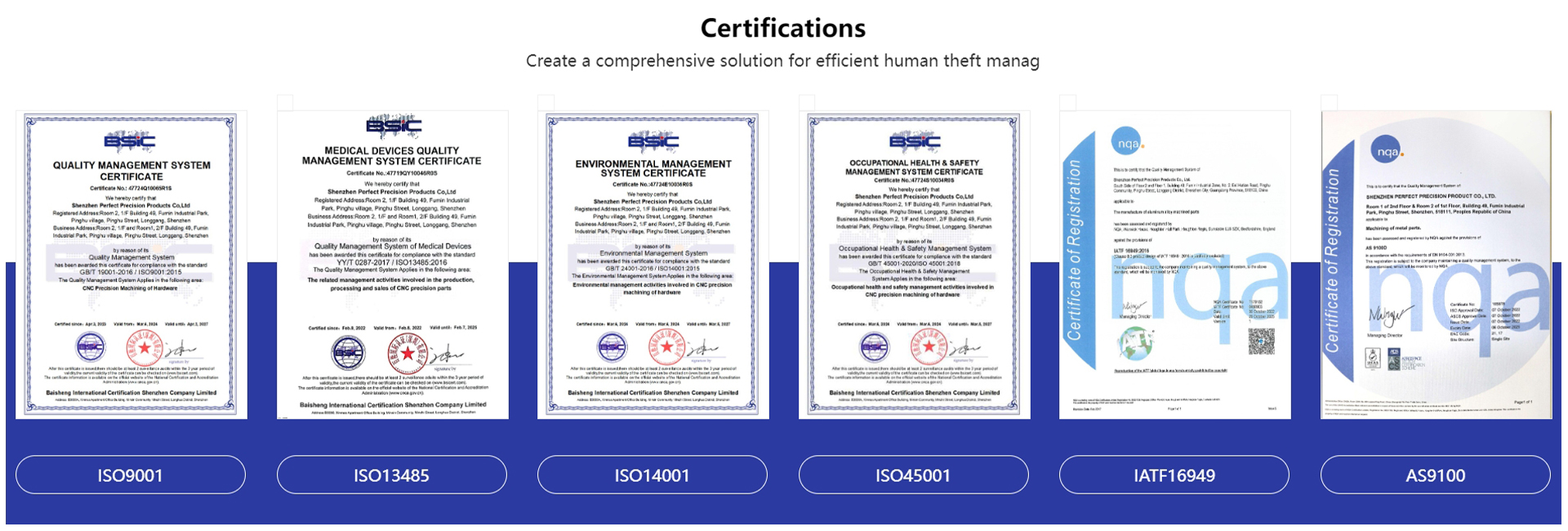

Standard : ISO

Finish : Customer request

MOQ : None

When you need CNC-turned or milled parts that last, surface treatments like plating and anodizing make all the difference. Whether it's for corrosion resistance, better aesthetics, or improved durability, these finishing processes take stainless steel fabrication to the next level.

Stainless steel is already tough, but nickel plating or hard-coat anodizing adds extra protection against rust and chemicals.

Anodizing forms a hard oxide layer, while electroless nickel plating improves surface hardness.

Want a sleek black, gold, or colored finish? Anodizing offers custom colors, while plating can give a polished chrome look.

Some plated coatings (like silver or gold) enhance conductivity for electronics.

| Feature | Plating | Anodizing |

|---|---|---|

| Process | Electrochemical metal deposition (e.g., nickel, chrome, zinc) | Electrochemical oxidation (for aluminum, titanium) |

| Best For | Stainless steel, brass, copper | Aluminum, titanium (not for bare steel) |

| Thickness | 0.005mm – 0.05mm | 0.01mm – 0.1mm (hard anodizing) |

| Appearance | Metallic shine (chrome, gold, etc.) | Matte or colored finishes |

| Durability | Good wear resistance | Extremely hard surface |

✔ Uniform coating (even on complex geometries)

✔ High corrosion & wear resistance

✔ Common in aerospace and medical devices

✔ Super shiny, decorative finish

✔ Good for wear resistance (but not as tough as ENP)

✔ Used in electronics for conductivity

✔ Premium look for luxury goods

Since anodizing doesn’t work on steel, it’s perfect for aluminum-machined components.

Plating and anodizing aren’t just about looks—they extend the life and performance of CNC-machined parts. Whether you’re building medical implants, automotive sensors, or high-end consumer products, the right finish ensures durability and functionality.

1. Are you a manufacturer or a trading company?

|

|

Plated Anodizing CNC Turning Milling Parts Stainless Steel Fabrication Images |