If you're sourcing CNC-turned parts for industrial, aerospace, or medical applications, you’ve probably considered aluminum and titanium rods. Both are popular in precision machining, but they serve different needs.

Aluminum Service Metal Rods: Lightweight & Cost-Effective

Aluminum is a go-to for CNC turning because it’s easy to machine, lightweight, and corrosion-resistant. Common grades like 6061 and 7075 are used in everything from automotive components to electronics.

Key Benefits of Aluminum CNC Turning:

- Fast Machining – Softer than titanium, so cutting speeds are higher (reducing costs).

- Good Strength-to-Weight Ratio – Perfect for parts where weight matters (e.g., drones, medical devices).

- Natural Corrosion Resistance – Doesn’t rust, making it great for outdoor or marine applications.

- Affordable – Much cheaper than titanium, ideal for high-volume production.

Best Uses for Aluminum Rods:

- Brackets & housings (electronics, automotive)

- Prototypes (quick, low-cost machining)

- Heat sinks (excellent thermal conductivity)

Titanium CNC Turning Parts: Strength & Biocompatibility

Titanium is stronger, more durable, and biocompatible—but also more expensive and harder to machine. Grades like Ti-6Al-4V (Grade 5) are common in aerospace and medical implants.

Key Benefits of Titanium CNC Turning:

- Extreme Strength – Comparable to steel but 45% lighter.

- Biocompatible – Safe for surgical implants and medical tools.

- Heat & Corrosion Resistant – Handles harsh environments (chemical, aerospace).

- Long Lifespan – Resists wear better than aluminum.

Challenges of Titanium Machining:

- Slower Cutting Speeds – Harder material means longer machining time.

- Higher Tool Wear – Requires specialized carbide tools.

- More Expensive – Raw material costs 5-10x more than aluminum.

Best Uses for Titanium Rods:

- Aircraft components (landing gear, engine parts)

- Medical implants (bone screws, dental posts)

- High-stress industrial parts (valves, fasteners)

| | CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding,3D Printing,Rapid Prototype,Moulds etc. |

| | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

| Titanium: Grade F1-F5 |

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. |

| | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| | ±0.002 ~ ±0.005mm |

| | Min Ra 0.1~3.2 |

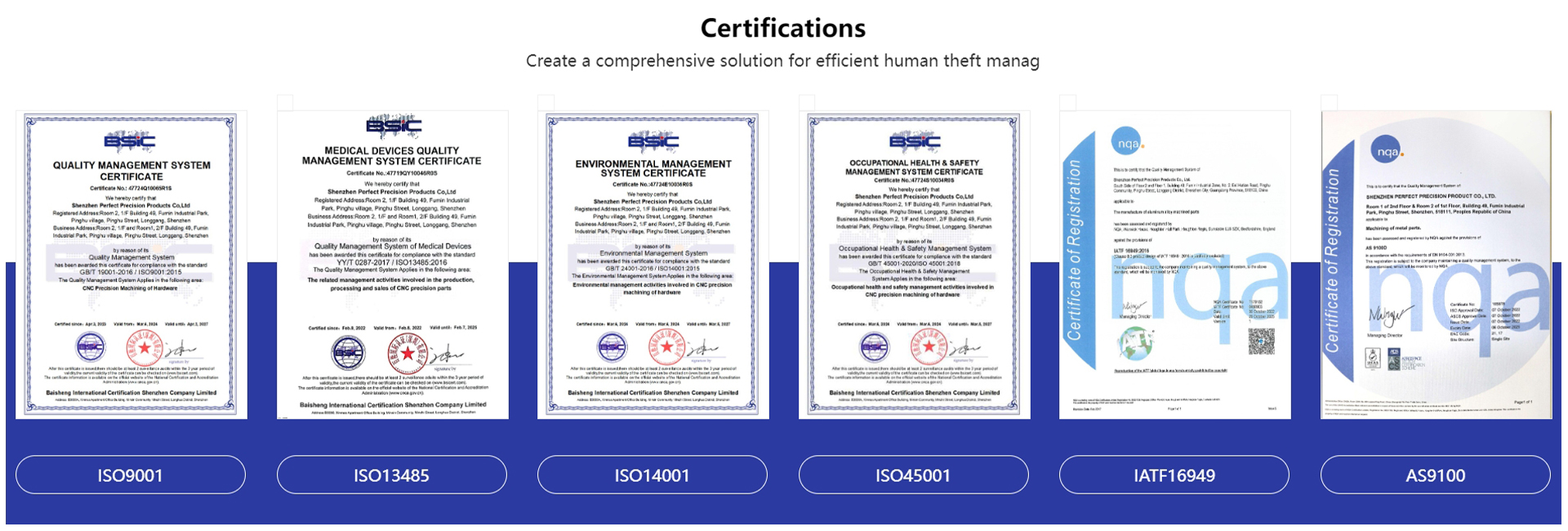

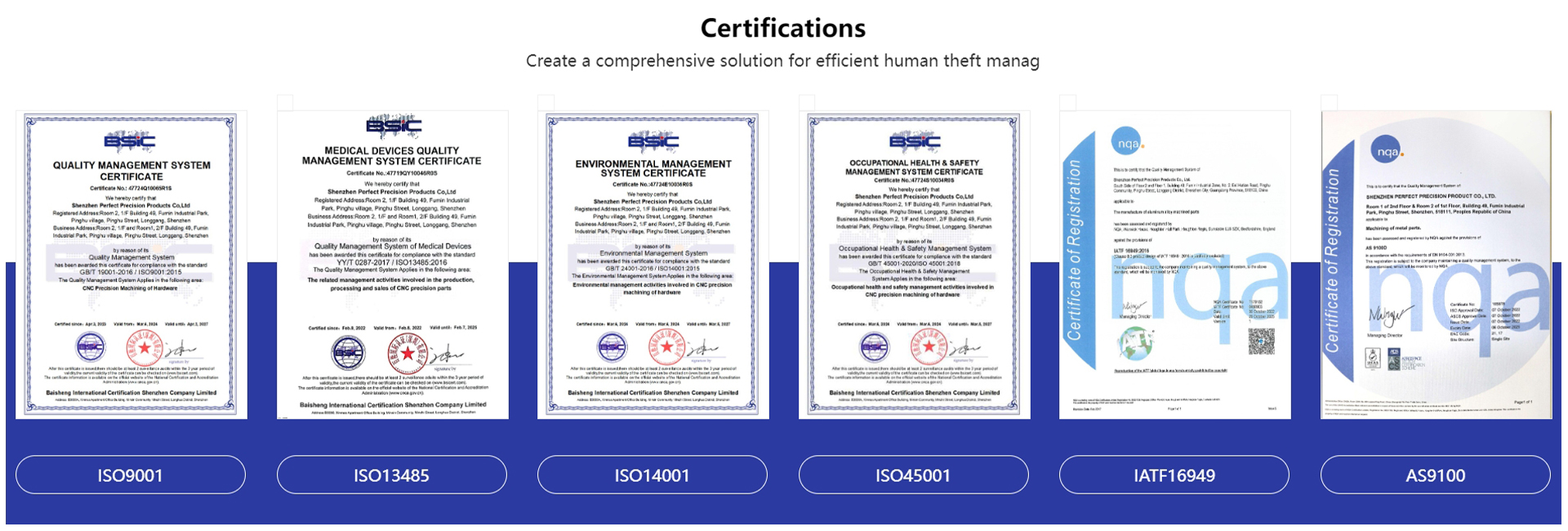

| CERTIFICATE | ISO9001:2015,AS9100D,ISO13485:2016,ISO45001:2018,IATF16949:2016,ISO14001:2015,ROSH,CE etc. |

FAQ

1. Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 20 years of rich experience,

covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings?

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure

critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

Product Tags:

|

|

Aluminum Service Metal Rod Titanium CNC Turning Parts Images

|